General guidelines for choosing rubber gasket materials

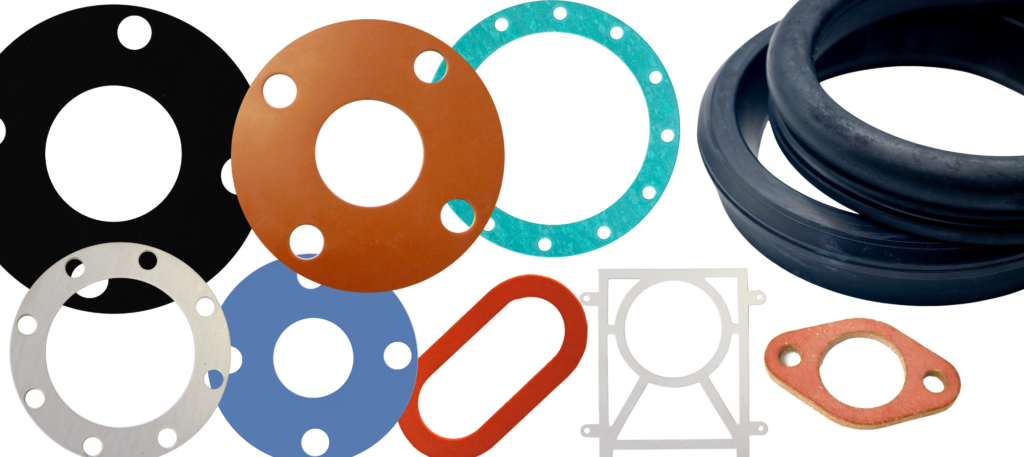

Rubber gasket materials are crucial components in many industrial and mechanical applications. They are used to seal joints and prevent fluid or gas leakage, making them essential in a wide range of industries, from automotive, marine, and aerospace to construction and mining. They also offer excellent resistance to heat, cold, and chemicals, making them ideal for use in harsh environments.

Rubber elastomers can be manufactured into different gasket shapes and sizes to meet specific application requirements. Some common gasket shapes include round, square, oval, and rectangular; they can also be custom-made based on application. With so many different types of rubber gasket materials available, it can be difficult to choose the right one for your needs. In this guide, we will cover some of the most common rubber gasket materials and their uses.

Nitrile Rubber (Buna-N)

Nitrile, also known as Buna-N, is a popular synthetic elastomer that is manufactured from a copolymer of acrylonitrile and butadiene. This material is ideal for machinery gaskets and is perfect for those in and around oil and gas handling equipment due to its high resistance to oil and gasoline. It is also a great choice for gasket materials that will be in contact with hydrocarbons.

Available selections of Nitrile Rubber include:

Nitrile (Buna-N)

Temp -20 to +170 °F

Nitrile (AB-365)

Temp -20 to +190 °F

Nitrile (AB-375)

Temp -20 to +200 °F

Nitrile (Garlock® 9122)

Temp -20 to +250 °F

Nitrile (Robco® 9863)

Temp -40 to +200 °F

Nitrile (Transeal®)

Temp -20 to +250 °F

Nitrile MIL-R-6855

Temp -50 to +220 °F

Nitrile Nylon Insert

Temp -20 to +120 °F

White Nitrile

Temp -20 to +170 °F

White Nitrile FDA

Temp -40 to +200 °F

Neoprene Rubber

Neoprene generally has an overall good weathering and compression resistance. It has flame retarding properties and also has resistance to petroleum-based fluids. It can resist moderate chemicals and acids, ozone, sunlight, Oil, fats, greases, and many solvents.

Available selections of Neoprene Rubber include:

Neoprene

Temp -20 to +170 °F

Neoprene (AB-245)

Temp -20 to +190 °F

Neoprene (AB-255)

Temp -20 to +190 °F

Neoprene (AB-260)

Temp -20 to +190 °F

Neoprene (Garlock® 7986)

Temp -20 to +250

Neoprene (Cloth Insert)

Temp -20 to +170 °F

Neoprene (Fabric Finish)

Temp -20 to +170 °F

Neoprene (Nylon Insert)

Temp -20 to +170 °F

Silicone Rubber

Silicone rubber products are known to have excellent resistance to ozone, oxidation, ultraviolet light, corona discharge, cosmic radiation, ionizing radiation, fungus, and weathering in general. Furthermore, silicone rubber is an excellent choice for any gasket and sealing solutions that require resistance to extremely high and low temperatures and it is easily die cut. Silicone comes in different variations including FDA grade which is common in food applications.

Available selections of Silicone Rubber include:

Silicone Black

Temp -76 to +446 °F

Silicone FDA (metectSil™)

Temp -76 to +392 °F

Silicone FDA Red

Temp -76 to +392 °F

Silicone FDA White

Temp -76 to +392 °F

Silicone Grey

Temp -76 to +446 °F

Silicone Red

Temp -76 to +446 °F

EPDM Rubber

EPDM rubber is a synthetic rubber that is known for its resistance to weathering, ozone, and chemicals. It is a high-density synthetic rubber used most commonly as a sealing material in the Marine, Construction, and Automotive industries due to its excellent resistance to environmental factors such as ozone, steam, weathering, and UV. EPDM is suitable for outdoor applications as it has excellent water, heat, chemical and aging resistance, with general resistance to strong oxidizing chemicals and acetone.

Available selections of EPDM Rubber include:

EPDM

Temp -40 to +212 °F

EPDM (AB-576) NSF-61

Temp -40 to +275 °F

EPDM (Garlock® 98206)

Temp -40 to +275 °F

EPDM, Peroxide-cured

Temp -4 to +300 °

Natural Rubber

Natural rubber is a natural product that is made from the sap of rubber trees. It exhibits a number of positive characteristics including superior resilience, high abrasion and tear resistance, high tensile strength, good compression set, excellent electric insulation qualities, elongation, and molding properties. The gum rubber material also creates a soft seal and displays good flexibility at low temperatures. This elastomer has the ability to bond with other materials such as metal and is soft enough to conform to irregular flanges with bolt heads.

Available selections of Natural Rubber include:

Natural Rubber

Temp -40 to +158 °F

Butyl Rubber

Butyl is a black synthetic elastomer, also known as the copolymer Isobutylene-isoprene (IIR). Used in many commercial and industrial applications, Butyl is a great general purpose rubber as it has good shock absorption characteristics, low moisture, and gas permeability. It is also the only known elastomer that is impervious to gases. Butyl rubber is flexible, with good room temperature damping characteristics. It also resists many acidic and alkaline chemicals and has good aging properties. Good to Excellent resistance: Flex Cracking and Abrasion, Weather, Sunlight, Oxidation, Ozone and UV, Chemicals, Potable, Drinking Water, Steam, and Gas Permeability.

Available selections of Butyl Rubber include:

Butyl

Temp -30 to +170 °F

Viton™ Rubber

Viton™ is a type of synthetic rubber made from a combination of fluoropolymer and carbon monomer. It is known for its exceptional resistance to heat, chemicals, and oil. Viton™ rubber is highly resistant to a wide range of chemicals making it a popular choice for use in industries such as automotive, aerospace, chemical processing, and oil & gas. It is also highly resistant to high temperatures, withstanding temperatures up to 400 degrees Fahrenheit (200 degrees ° Celsius).

Available selections of Viton Rubber include:

Viton™ Black

Temp -20 to +400 °F

Viton™ Brown

Temp -10 to +400 °F

Viton™ FDA White

Temp -20 to +400 °F

Viton™ with 1-PLY Nomex®

Temp -13 to +450 °F

Styrene Butadiene Rubber (SBR)

Styrene Butadiene Rubber (SBR) is synthetic, low-cost rubber material comprised of styrene and butadiene monomers. It is made as a replacement for natural rubber to serve the wide-range demands of various industries. This rubber gasket material is specially designed to be quick-sealing, non-hardening, and heat-resistant for use in various flanged applications.

However, this material has poor resistance to ozone, sunlight, strong solvents, most hydrocarbons, mineral oil, and petroleum-based fluids and its fatigue resistance and low temperature properties remain inferior to natural rubber.

Available selections of SBR include:

SBR

Temp -20 to +170 °F

SBR (GRT® 22)

Temp -20 to +180 °F

SBR C.I. (Cloth Inserted)

Temp -20 to +170 °F

SBR F.F. (Fabric Finish)

Temp -20 to +170 °F

SBR Red

Temp -20 to +120 °F

SBR Red F.F. (Fabric Finish)

Temp -20 to +120 °F

BR Runner Matting

Temp -22 to +176 °F

Choosing the right rubber gasket material depends on the specific requirements of your application. Consider factors such as temperature, pressure, chemical exposure, and the environment when selecting a material for your gasket. By understanding the properties of these common rubber gasket materials, you can make an informed decision and ensure that your gasket meets the needs of your application.

Custom Gaskets specializes in creating custom-shaped gaskets of any size to meet customer requirements. Using an advanced CNC machine with great precision, combined with our 55 years of experience enables the team to construct the highest quality sealing products. Whether you are looking for high or low-volume production, Custom Gaskets is here to support your ideas and produce sealing solutions for your applications.