Spiral Wound Gaskets

Dimensions for Spiral Wound Gaskets used with ASME B16.5 Pipe Flanges

Spiral Wound Gaskets (SWG) are the most common metallic gaskets used in industrial applications. SWG are engineered sealing elements made with an alternating combination of a preformed metal strip and a more compressible filler material which creates an excellent seal when compressed.

The Metal Strip Winding and Filler Material can be selected to seal a wide range of applications and acts as a spring under load, resulting in a very resilient seal under varying conditions. A properly selected and installed Spiral Wound Gasket can withstand high temperatures and pressures, preventing leaks throughout their intended lifespan.

Custom Gaskets Ltd. supplies a wide range of Spiral Wound Gaskets for your specific applications. We stock many of the two most common SWG styles manufactured by Flexitallic® and Durlon®, which are CGI/DRI with Inner Ring and CG/DR without Inner Ring. Both Spiral Wound Gaskets styles have been engineered to precise manufacturing tolerances and utilize optimal winding density that allow for lower stress (bolt load) sealing. Both SWG styles are suitable for either Flat Face and Raised Face flanges.

Spiral Wound Gaskets of Style CG/DR are designed to serve general purpose usage. The Outer Ring provides radial strength to prevent gasket blowout and helps to accurately center the gaskets on flange faces.

SWG of Style CGI/DRI are required for all Class 900 and above. Their design incorporates an Inner Ring for increased compressive force for blow-out prevention and is specified for high pressure/temperature service or where corrosive or toxic media are present. It prevents build-up of process fluid, minimizes erosion and turbulence, shields and prevents inward bucking of the gasket.

Custom Gaskets Ltd. readily carries the two most common styles of spiral wounds in stock, but is not limited to Styles CG/DR and CGI/DRI. We are also able to supply Styles R, RIR, HE, and Multi-Class upon request.

Spiral Wound Gasket Dimensions by Pressure Class

| Class 150 NPS | Style DRI ID | Style DR ID | Winding OD | SWG OD |

|---|---|---|---|---|

| 1/2” | 0.56 | 0.75 | 1.25 | 1.88 |

| 3/4” | 0.81 | 1 | 1.56 | 2.25 |

| 1″ | 1.06 | 1.25 | 1.88 | 2.63 |

| 1-1/4″ | 1.5 | 1.88 | 2.38 | 3 |

| 1-1/2″ | 1.75 | 2.13 | 2.75 | 3.38 |

| 2″ | 2.19 | 2.75 | 3.38 | 4.13 |

| 2-1/2″ | 2.62 | 3.25 | 3.88 | 4.88 |

| 3″ | 3.19 | 4 | 4.75 | 5.38 |

| 4″ | 4.19 | 5 | 5.88 | 6.88 |

| 5″ | 5.19 | 6.13 | 7 | 7.75 |

| 6″ | 6.19 | 7.19 | 8.25 | 8.75 |

| 8″ | 8.5 | 9.19 | 10.38 | 11 |

| 10″ | 10.56 | 11.31 | 12.5 | 13.38 |

| 12″ | 12.5 | 13.38 | 14.75 | 16.13 |

| 14″ | 13.75 | 14.63 | 16 | 17.75 |

| 16″ | 15.75 | 16.63 | 18.25 | 20.25 |

| 18″ | 17.69 | 18.69 | 20.75 | 21.63 |

| 20″ | 19.69 | 20.69 | 22.75 | 23.88 |

| 24″ | 23.75 | 24.75 | 27 | 28.25 |

| Series A | ||||

| 26″ | 25.75 | 26.5 | 27.75 | 30.5 |

| 28″ | 27.75 | 28.5 | 29.75 | 32.75 |

| 30″ | 29.75 | 30.5 | 31.75 | 34.75 |

| 32″ | 31.75 | 32.5 | 33.88 | 37 |

| 34″ | 33.75 | 34.5 | 35.88 | 39 |

| 36″ | 35.75 | 36.5 | 38.13 | 41.25 |

| 38″ | 37.75 | 38.5 | 40.13 | 43.75 |

| 40″ | 39.75 | 40.5 | 42.13 | 45.75 |

| 42″ | 41.75 | 42.5 | 44.25 | 48 |

| 44″ | 43.75 | 44.5 | 46.38 | 50.25 |

| 46″ | 45.75 | 46.5 | 48.38 | 52.25 |

| 48″ | 47.75 | 48.5 | 50.38 | 54.5 |

| 50″ | 49.75 | 50.5 | 52.5 | 56.5 |

| 52″ | 51.75 | 52.5 | 54.5 | 58.75 |

| 54″ | 53.5 | 54.5 | 56.5 | 61 |

| 56″ | 55.5 | 56.5 | 58.5 | 63.25 |

| 58″ | 57.5 | 58.5 | 60.5 | 65.5 |

| 60″ | 59.5 | 60.5 | 62.5 | 67.5 |

| Series B | ||||

| 26″ | 25.75 | 26.5 | 27.5 | 28.56 |

| 28″ | 27.75 | 28.5 | 29.5 | 30.56 |

| 30″ | 29.75 | 30.5 | 31.5 | 32.56 |

| 32″ | 31.75 | 32.5 | 33.5 | 34.69 |

| 34″ | 33.75 | 34.5 | 35.75 | 36.81 |

| 36″ | 35.75 | 36.5 | 37.75 | 38.88 |

| 38″ | 37.75 | 38.37 | 39.75 | 41.13 |

| 40″ | 39.75 | 40.25 | 41.88 | 43.13 |

| 42″ | 41.75 | 42.5 | 43.88 | 45.13 |

| 44″ | 43.75 | 44.25 | 45.88 | 47.13 |

| 46″ | 45.75 | 46.5 | 48.19 | 49.44 |

| 48″ | 47.75 | 48.5 | 50 | 51.44 |

| 50″ | 49.75 | 50.5 | 52.19 | 53.44 |

| 52″ | 51.75 | 52.5 | 54.19 | 55.44 |

| 54″ | 53.75 | 54.5 | 56 | 57.63 |

| 56″ | 56 | 56.88 | 58.18 | 59.63 |

| 58″ | 58.19 | 59.07 | 60.19 | 62.19 |

| 60″ | 60.44 | 61.31 | 62.44 | 64.19 |

| Class 300 NPS | Style DRI ID | Style DR ID | Winding OD | SWG OD |

|---|---|---|---|---|

| 1/2” | 0.56 | 0.75 | 1.25 | 2.13 |

| 3/4” | 0.81 | 1 | 1.56 | 2.63 |

| 1″ | 1.06 | 1.25 | 1.88 | 2.88 |

| 1-1/4″ | 1.5 | 1.88 | 2.38 | 3.25 |

| 1-1/2″ | 1.75 | 2.13 | 2.75 | 3.75 |

| 2″ | 2.19 | 2.75 | 3.38 | 4.38 |

| 2-1/2″ | 2.62 | 3.25 | 3.88 | 5.13 |

| 3″ | 3.19 | 4 | 4.75 | 5.88 |

| 4″ | 4.19 | 5 | 5.88 | 7.13 |

| 5″ | 5.19 | 6.13 | 7 | 8.5 |

| 6″ | 6.19 | 7.19 | 8.25 | 9.88 |

| 8″ | 8.5 | 9.19 | 10.38 | 12.13 |

| 10″ | 10.56 | 11.31 | 12.5 | 14.25 |

| 12″ | 12.5 | 13.38 | 14.75 | 16.63 |

| 14″ | 13.75 | 14.63 | 16 | 19.13 |

| 16″ | 15.75 | 16.63 | 18.25 | 21.25 |

| 18″ | 17.69 | 18.69 | 20.75 | 23.5 |

| 20″ | 19.69 | 20.69 | 22.75 | 25.75 |

| 24″ | 23.75 | 24.75 | 27 | 30.5 |

| Series A | ||||

| 26” | 25.75 | 27 | 29 | 32.88 |

| 28” | 27.75 | 29 | 31 | 35.38 |

| 30” | 29.75 | 31.25 | 33.25 | 37.5 |

| 32” | 31.75 | 33.5 | 35.5 | 39.63 |

| 34” | 33.75 | 35.5 | 37.5 | 41.63 |

| 36” | 35.75 | 37.63 | 39.63 | 44 |

| 38” | 37.5 | 38.5 | 40 | 41.5 |

| 40” | 39.5 | 40.25 | 42.13 | 43.88 |

| 42” | 41.5 | 42.25 | 44.13 | 45.88 |

| 44” | 43.5 | 44.5 | 46.5 | 48 |

| 46” | 45.38 | 46.38 | 48.38 | 50.13 |

| 48” | 47.63 | 48.63 | 50.63 | 52.13 |

| 50” | 49 | 51 | 53 | 54.25 |

| 52” | 52 | 53 | 55 | 56.25 |

| 54” | 53.25 | 55.25 | 57.25 | 58.75 |

| 56” | 55.25 | 57.25 | 59.25 | 60.75 |

| 58” | 57 | 59.5 | 61.5 | 62.75 |

| 60” | 60 | 61.5 | 63.5 | 64.75 |

| Series B | ||||

| 26” | 25.75 | 26.5 | 28 | 30.38 |

| 28” | 27.75 | 28.5 | 30 | 32.5 |

| 30” | 29.75 | 30.5 | 32 | 34.88 |

| 32” | 31.75 | 32.5 | 34 | 37 |

| 34” | 33.75 | 34.5 | 36 | 39.13 |

| 36” | 35.75 | 36.5 | 38 | 41.25 |

| 38” | 38.25 | 39.75 | 41.25 | 43.25 |

| 40” | 40.25 | 41.75 | 43.25 | 45.25 |

| 42” | 42.75 | 43.75 | 45.25 | 47.25 |

| 44” | 44.25 | 45.75 | 47.25 | 49.25 |

| 46” | 46.38 | 47.88 | 49.38 | 51.88 |

| 48” | 48.5 | 49.75 | 51.63 | 53.88 |

| 50” | 49.88 | 51.88 | 53.38 | 55.88 |

| 52” | 51.88 | 53.88 | 55.38 | 57.88 |

| 54” | 53.75 | 55.25 | 57.25 | 60.25 |

| 56” | 56.25 | 58.25 | 60 | 62.75 |

| 58” | 58.44 | 60.44 | 61.94 | 65.19 |

| 60” | 61.31 | 62.56 | 64.19 | 67.19 |

| Class 400 NPS | Style DRI ID | Style DR ID | Winding OD | SWG OD |

|---|---|---|---|---|

| 1/2” | 0.56(1) | 0.75(1) | 1.25 | 2.13(1) |

| 3/4” | 0.81(1) | 1(1) | 1.56 | 2.63(1) |

| 1″ | 1.06(1) | 1.25(1) | 1.88 | 2.88(1) |

| 1-1/4″ | 1.5(1) | 1.88(1) | 2.38 | 3.25(1) |

| 1-1/2″ | 1.75(1) | 2.13(1) | 2.75 | 3.75(1) |

| 2″ | 2.19(1) | 2.75(1) | 3.38 | 4.38(1) |

| 2-1/2″ | 2.62(1) | 3.25(1) | 3.88 | 5.13(1) |

| 3″ | 3.1(1) | 4(1) | 4.75 | 5.88(1) |

| 4″ | 4.04 | 4.75 | 5.88 | 7 |

| 5″ | 5.05 | 5.81 | 7 | 8.38 |

| 6″ | 6.1 | 6.88 | 8.25 | 9.75 |

| 8″ | 8.1 | 8.88 | 10.38 | 12 |

| 10″ | 10.05 | 10.81 | 12.5 | 14.13 |

| 12″ | 12.1 | 12.88 | 14.75 | 16.5 |

| 14″ | 13.5 | 14.25 | 16 | 19 |

| 16″ | 15.35 | 16.25 | 18.25 | 21.13 |

| 18″ | 17.25 | 18.5 | 20.75 | 23.38 |

| 20″ | 19.25 | 20.5 | 22.75 | 25.5 |

| 24″ | 23.25 | 24.75 | 27 | 30.25 |

| Series A | ||||

| 26″ | 26 | 27 | 29 | 32.75 |

| 28″ | 28 | 29 | 31 | 35.13 |

| 30″ | 29.75 | 31.25 | 33.25 | 37.25 |

| 32″ | 32 | 33.5 | 35.5 | 39.5 |

| 34″ | 34 | 35.5 | 37.5 | 41.5 |

| 36″ | 36.13 | 37.63 | 39.63 | 44 |

| 38″ | 37.5 | 38.25 | 40.25 | 42.25 |

| 40″ | 39.38 | 40.38 | 42.38 | 44.38 |

| 42″ | 41.38 | 42.38 | 44.38 | 46.38 |

| 44″ | 43.5 | 44.5 | 46.5 | 48.5 |

| 46″ | 46 | 47 | 49 | 50.75 |

| 48″ | 47.5 | 49 | 51 | 53 |

| 50″ | 49.5 | 51 | 53 | 55.25 |

| 52″ | 51.5 | 53 | 55 | 57.25 |

| 54″ | 53.25 | 55.25 | 57.25 | 59.75 |

| 56″ | 55.25 | 57.25 | 59.25 | 61.75 |

| 58″ | 57.25 | 59.25 | 61.25 | 63.75 |

| 60″ | 59.75 | 61.75 | 63.75 | 66.25 |

| Series B | ||||

| 26″ | 25.75 | 26.25 | 27.5 | 29.38 |

| 28″ | 27.63 | 28.13 | 29.5 | 31.5 |

| 30″ | 29.63 | 30.13 | 31.75 | 33.75 |

| 32″ | 31.5 | 32 | 33.88 | 35.88 |

| 34″ | 33.5 | 34.13 | 35.88 | 37.88 |

| 36″ | 35.38 | 36.13 | 38 | 40.25 |

| 38″ | 37.5 | 38.25 | 40.25 | 42.25 |

| 40″ | 39.38 | 40.38 | 42.38 | 44.38 |

| 42″ | 41.38 | 42.38 | 44.38 | 46.38 |

| 44″ | 43.5 | 44.5 | 46.5 | 48.5 |

| 46″ | 46 | 47 | 49 | 50.75 |

| 48″ | 47.5 | 49 | 51 | 53 |

| 50″ | 49.5 | 51 | 53 | 55.25 |

| 52″ | 51.5 | 53 | 55 | 57.25 |

| 54″ | 53.25 | 55.25 | 57.25 | 59.75 |

| 56″ | 55.25 | 57.25 | 59.25 | 61.75 |

| 58″ | 57.25 | 59.25 | 61.25 | 63.75 |

| 60″ | 59.75 | 61.75 | 63.75 | 66.25 |

| Class 600 NPS | Style DRI ID | Style DR ID | Winding OD | SWG OD |

|---|---|---|---|---|

| 1/2” | 0.56 | 0.75 | 1.25 | 2.13 |

| 3/4” | 0.81 | 1 | 1.56 | 2.63 |

| 1″ | 1.06 | 1.25 | 1.88 | 2.88 |

| 1-1/4″ | 1.5 | 1.88 | 2.38 | 3.25 |

| 1-1/2″ | 1.75 | 2.13 | 2.75 | 3.75 |

| 2″ | 2.19 | 2.75 | 3.38 | 4.38 |

| 2-1/2″ | 2.62 | 3.25 | 3.88 | 5.13 |

| 3″ | 3.1 | 4 | 4.75 | 5.88 |

| 4″ | 4.04 | 5 | 5.88 | 7.13 |

| 5″ | 6.05 | 6.13 | 7 | 8.5 |

| 6″ | 6.1 | 7.19 | 8.25 | 9.88 |

| 8″ | 8.1 | 9.19 | 10.38 | 12.13 |

| 10″ | 10.05 | 11.31 | 12.5 | 14.25 |

| 12″ | 12.1 | 13.38 | 14.75 | 16.63 |

| 14″ | 13.5 | 14.63 | 16 | 19.13 |

| 16″ | 15.35 | 16.63 | 18.25 | 21.25 |

| 18″ | 17.25 | 18.69 | 20.75 | 23.5 |

| 20″ | 19.25 | 20.69 | 22.75 | 25.75 |

| 24″ | 23.25 | 24.75 | 27 | 30.5 |

| Series A | ||||

| 26″ | 25.5 | 27 | 29 | 34.13 |

| 28″ | 27.5 | 29 | 31 | 36 |

| 30″ | 29.75 | 31.25 | 33.25 | 38.25 |

| 32″ | 32 | 33.5 | 35.5 | 40.25 |

| 34″ | 34 | 35.5 | 37.5 | 42.25 |

| 36″ | 36.13 | 37.63 | 39.63 | 44.5 |

| 38″ | 37.5 | 39 | 41 | 43.5 |

| 40″ | 39.75 | 41.25 | 43.25 | 45.5 |

| 42″ | 42 | 43.5 | 45.5 | 48 |

| 44″ | 43.75 | 45.75 | 47.75 | 50 |

| 46″ | 45.75 | 47.75 | 49.75 | 52.25 |

| 48″ | 48 | 50 | 52 | 54.75 |

| 50″ | 50 | 52 | 54 | 57 |

| 52″ | 52 | 54 | 56 | 59 |

| 54″ | 54.25 | 56.25 | 58.25 | 61.25 |

| 56″ | 56.25 | 58.25 | 60.25 | 63.5 |

| 58″ | 58 | 60.5 | 62.5 | 65.5 |

| 60″ | 60.25 | 62.75 | 64.75 | 68.25 |

| Series B | ||||

| 26″ | 25.38 | 26.13 | 28.13 | 30.13 |

| 28″ | 27 | 27.75 | 29.75 | 32.25 |

| 30″ | 29.63 | 30.63 | 32.63 | 34.63 |

| 32″ | 31.25 | 32.75 | 34.75 | 36.75 |

| 34″ | 33.5 | 35 | 37 | 39.25 |

| 36″ | 35.5 | 37 | 39 | 41.25 |

| 38″ | 37.5 | 39 | 41 | 43.5 |

| 40″ | 39.75 | 41.25 | 43.25 | 45.5 |

| 42″ | 42 | 43.5 | 45.5 | 48 |

| 44″ | 43.75 | 45.75 | 47.75 | 50 |

| 46″ | 45.75 | 47.75 | 49.75 | 52.25 |

| 48″ | 48 | 50 | 52 | 54.75 |

| 50″ | 50 | 52 | 54 | 57 |

| 52″ | 52 | 54 | 56 | 59 |

| 54″ | 54.25 | 56.25 | 58.25 | 61.25 |

| 56″ | 56.25 | 58.25 | 60.25 | 63.5 |

| 58″ | 58 | 60.5 | 62.5 | 65.5 |

| 60″ | 60.25 | 62.75 | 64.75 | 68.25 |

| Class 900 NPS | Style DRI ID | Style DR ID | Winding OD | SWG OD |

|---|---|---|---|---|

| 1/2” | 0.56(1) | 0.75(1) | 1.25 | 2.50(1) |

| 3/4” | 0.81(1) | 1(1) | 1.56 | 2.75(1) |

| 1″ | 1.06(1) | 1.25(1) | 1.88 | 3.13(1) |

| 1-1/4″ | 1.31(1) | 1.88(1) | 2.38 | 3.5(1) |

| 1-1/2″ | 1.63(1) | 2.13(1) | 2.75 | 3.88(1) |

| 2″ | 2.06(1) | 2.75(1) | 3.38 | 5.63(1) |

| 2-1/2″ | 2.5(1) | 3.25(1) | 3.88 | 6.5(1) |

| 3″ | 3.1 | 3.75 | 4.75 | 6.63 |

| 4″ | 4.04 | 4.75 | 5.88 | 8.13 |

| 5″ | 6.05 | 5.81 | 7 | 9.75 |

| 6″ | 6.1 | 6.88 | 8.25 | 11.38 |

| 8″ | 7.75 | 8.75 | 10.13 | 14.13 |

| 10″ | 9.69 | 10.88 | 12.25 | 17.13 |

| 12″ | 11.5 | 12.75 | 14.5 | 19.63 |

| 14″ | 12.63 | 14 | 15.75 | 20.5 |

| 16″ | 14.75 | 16.25 | 18 | 22.63 |

| 18″ | 16.75 | 18.25 | 20.5 | 25.13 |

| 20″ | 19 | 20.5 | 22.5 | 27.5 |

| 24″ | 23.25 | 24.75 | 26.75 | 33 |

| Series A | ||||

| 26″ | 26 | 27 | 29 | 34.75 |

| 28″ | 28 | 29 | 31 | 37.25 |

| 30″ | 30.25 | 31.25 | 33.25 | 39.75 |

| 32″ | 32 | 33.5 | 35.5 | 42.25 |

| 34″ | 34 | 35.5 | 37.5 | 44.75 |

| 36″ | 36.25 | 37.75 | 39.75 | 47.25 |

| 38″ | 39.75 | 40.75 | 42.75 | 47.25 |

| 40″ | 41.75 | 43.25 | 45.25 | 49.25 |

| 42″ | 43.75 | 45.25 | 47.25 | 51.25 |

| 44″ | 45.5 | 47.5 | 49.5 | 53.88 |

| 46″ | 48 | 50 | 52 | 56.5 |

| 48″ | 50 | 52 | 54 | 58.5 |

| Series B | ||||

| 26″ | 26.25 | 27.25 | 29.5 | 33 |

| 28″ | 28.25 | 29.25 | 31.5 | 35.5 |

| 30″ | 30.75 | 31.75 | 33.75 | 37.75 |

| 32″ | 33 | 34 | 36 | 40 |

| 34″ | 35.25 | 36.25 | 38.25 | 42.25 |

| 36″ | 36.25 | 37.25 | 39.25 | 44.25 |

| 38″ | 39.75 | 40.75 | 42.75 | 47.25 |

| 40″ | 41.75 | 43.25 | 45.25 | 49.25 |

| 42″ | 43.75 | 45.25 | 47.25 | 51.25 |

| 44″ | 45.5 | 47.5 | 49.5 | 53.88 |

| 46″ | 48 | 50 | 52 | 56.5 |

| 48″ | 50 | 52 | 54 | 58.5 |

| Class 1500 NPS | Style DRI ID | Style DR ID | Winding OD | SWG OD |

|---|---|---|---|---|

| 1/2” | 0.56 | 0.75 | 1.25 | 2.50 |

| 3/4” | 0.81 | 1 | 1.56 | 2.75 |

| 1″ | 1.06 | 1.25 | 1.88 | 3.13 |

| 1-1/4″ | 1.31 | 1.88 | 2.38 | 3.5 |

| 1-1/2″ | 1.63 | 2.13 | 2.75 | 3.88 |

| 2″ | 2.06 | 2.75 | 3.38 | 5.63 |

| 2-1/2″ | 2.5 | 3.25 | 3.88 | 6.5 |

| 3″ | 3.1 | 4 | 4.75 | 6.88 |

| 4″ | 3.85 | 5 | 5.88 | 8.25 |

| 5″ | 4.9 | 6.13 | 7 | 10 |

| 6″ | 5.8 | 7.19 | 8.25 | 11.13 |

| 8″ | 7.75 | 9.19 | 10.13 | 13.88 |

| 10″ | 9.69 | 11.31 | 12.25 | 17.13 |

| 12″ | 11.5 | 13.38 | 14.5 | 20.5 |

| 14″ | 12.63 | 14.63 | 15.75 | 22.75 |

| 16″ | 14.5 | 16.63 | 18 | 25.25 |

| 18″ | 16.75 | 18.69 | 20.5 | 27.27 |

| 20″ | 18.75 | 20.69 | 22.5 | 29.75 |

| 24″ | 22.75 | 24.75 | 26.75 | 35.5 |

| Class 2500(1) NPS | Style DRI ID | Style DR ID | Winding OD | SWG OD |

|---|---|---|---|---|

| 1/2” | 0.56 | 0.75 | 1.25 | 2.75 |

| 3/4” | 0.81 | 1 | 1.56 | 3 |

| 1″ | 1.06 | 1.25 | 1.88 | 3.38 |

| 1-1/4″ | 1.31 | 1.56 | 2.38 | 4.13 |

| 1-1/2″ | 1.63 | 1.88 | 2.75 | 4.63 |

| 2″ | 2.06 | 2.31 | 3.38 | 5.75 |

| 2-1/2″ | 2.5 | 2.75 | 3.88 | 6.63 |

| 3″ | 3.1 | 3.63 | 4.75 | 7.75 |

| 4″ | 3.85 | 4.63 | 5.88 | 9.25 |

| 5″ | 4.9 | 5.63 | 7 | 11 |

| 6″ | 5.8 | 6.75 | 8.25 | 12.5 |

| 8″ | 7.75 | 8.5 | 10.13 | 15.25 |

| 10″ | 9.69 | 10.63 | 12.25 | 18.75 |

| 12″ | 11.5 | 12.5 | 14.5 | 21.63 |

NPS = Nominal Pipe Size

ID = Inner Diameter

OD = Outer Diameter

SWG = Spiral Wound Gasket

General Notes:

(1) There are no Class 400 flanges in NPS 1/2” through 3” (use Class 600)

There are no Class 900 flanges in NPS 1/2” through 2-1/2” (use Class 1500)

There are no Class 2500 flanges in NPS 14” and larger

All dimensions are in inches.

Temperature Limits for common SWG Materials

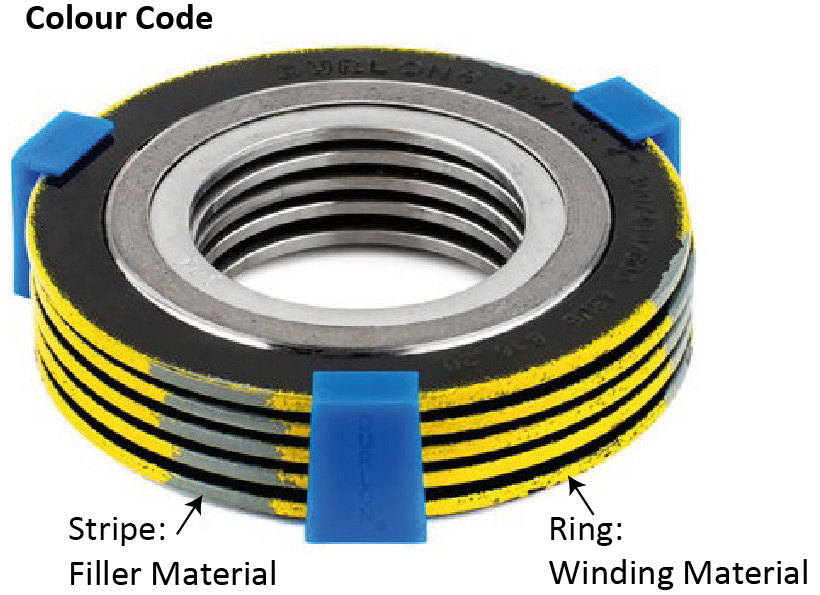

| Material | Lower Limit | Upper Limit | Abbreviation | Ring Colour Code |

|---|---|---|---|---|

| 304 Stainless Steel | -320°F (-195°C) | 1400°F (760°C) | 304 | Yellow |

| 316L Stainless Steel | -150°F (-100°C) | 1400°F (760°C) | 316L | Green |

| 317L Stainless Steel | -150°F (-100°C) | 1400°F (760°C) | 317L | Maroon |

| 321 Stainless Steel | -320°F (-195°C) | 1400°F (760°C) | 321 | Turquoise |

| 347 Stainless Steel | -320°F (-195°C) | 1700°F (925°C) | 347 | Blue |

| Carbon Steel | -40°F (-40°C) | 1000°F (540°C) | CRS | Silver |

| 20Cb-3 (Alloy 20) | -300°F (-185°C) | 1400°F (760°C) | A-20 | Black |

| Hastelloy® B2 | -300°F (-185°C) | 2000°F (1090°C) | HAST B | Brown |

| Hastelloy® C276 | -300°F (-185°C) | 2000°F (1090°C0 | HAST C | Beige |

| Incoloy® 800 | -150°F (-100°C) | 1600°F (870°C) | IN 800 | White |

| Incoloy® 825 | -150°F (-100°C) | 1600°F (870°C0 | IN 825 | White |

| Inconel® 600 | -150°F (-100°C) | 2000°F (1090°C) | INC 600 | Gold |

| Inconel® 625 | -150°F (-100°C) | 2000°F (1090°C) | INC 625 | Gold |

| Inconel® X750 | -150°F (-100°C) | 2000°F (1090°C) | INX | No Colour |

| Monel® 400 | -200°F (-130°C) | 1500°F (820°C) | MON | Orange |

| Nickel 200 | -320°F (-195°C) | 1400°F (760°C) | NI | Red |

| Titanium | -320°F (-195°C) | 2000°F (1090°C) | TI | Purple |

| Material | Lower Limit | Upper Limit | Abbreviation | Stripe Colour Code |

|---|---|---|---|---|

| PTFE | -400°F (-240°C) | 500°F (260°C) | PTFE | White |

| Flexible Graphite | -350°F (-212°C) | 950°F (510°C) | F.G. | Grey |

| Mica Graphite | -350°F (-212°C) | 1400°F (345°C) | MICA | Pink |

| Phyllosilicate | -67°F (-55°C) | 1800°F (1000°C) | ETG | Light Blue |