Selecting the Right Foam Material for Effective Sealing Applications

Foam is widely used for sealing due to its flexibility and ability to compress and adapt to uneven surfaces. It fills gaps effectively and maintains contact where rigid materials may not.

In everyday use, foam is commonly found around doors and windows, inside appliances, and in areas where noise or vibration needs to be reduced. In commercial and industrial settings, foam sealing materials are used in equipment panels, HVAC systems, and electrical enclosures to help control air, dust, moisture, and vibration.

The versatility of foam comes from the range of materials available, each suited for different conditions and performance needs. Choosing the right foam starts with understanding how it will be used and what matters most for the seal.

What Is Foam Material?

Foam is a type of polymer material made with a cell structure that traps air inside. This structure makes foam lightweight, compressible, and flexible, which is why it is commonly used for sealing and gasket applications.

In foam sealing applications, the material compresses to fill gaps and uneven surfaces, helping block air, dust, and moisture. When pressure is released, the foam recovers and continues to maintain contact between surfaces. This makes foam gasket materials effective where movement, vibration, or small tolerances are present.

Cell Structure: Open-Cell vs. Closed-Cell Foam

- Open-cell foam: Has connected cells that allow air and moisture to pass through. It is soft and flexible, often used for cushioning or sound control rather than sealing.

- Closed-cell foam: Has sealed cells that resist air and moisture. This makes closed-cell foam a common choice for foam seals and gaskets.

Key Properties That Affect Sealing

- Foam density: Affects how firm the foam feels and how well it holds up under pressure.

- Compression set: Describes how well the foam returns to its original thickness after being compressed.

- Recovery: Refers to how quickly the foam rebounds, which helps maintain a consistent seal over time.

Key takeaway: For most sealing applications, closed-cell foam materials provide better sealing performance than open-cell foam.

Not sure which foam material you need? Talk to a material specialist for guidance based on your application.

Common Foam Materials Used for Sealing

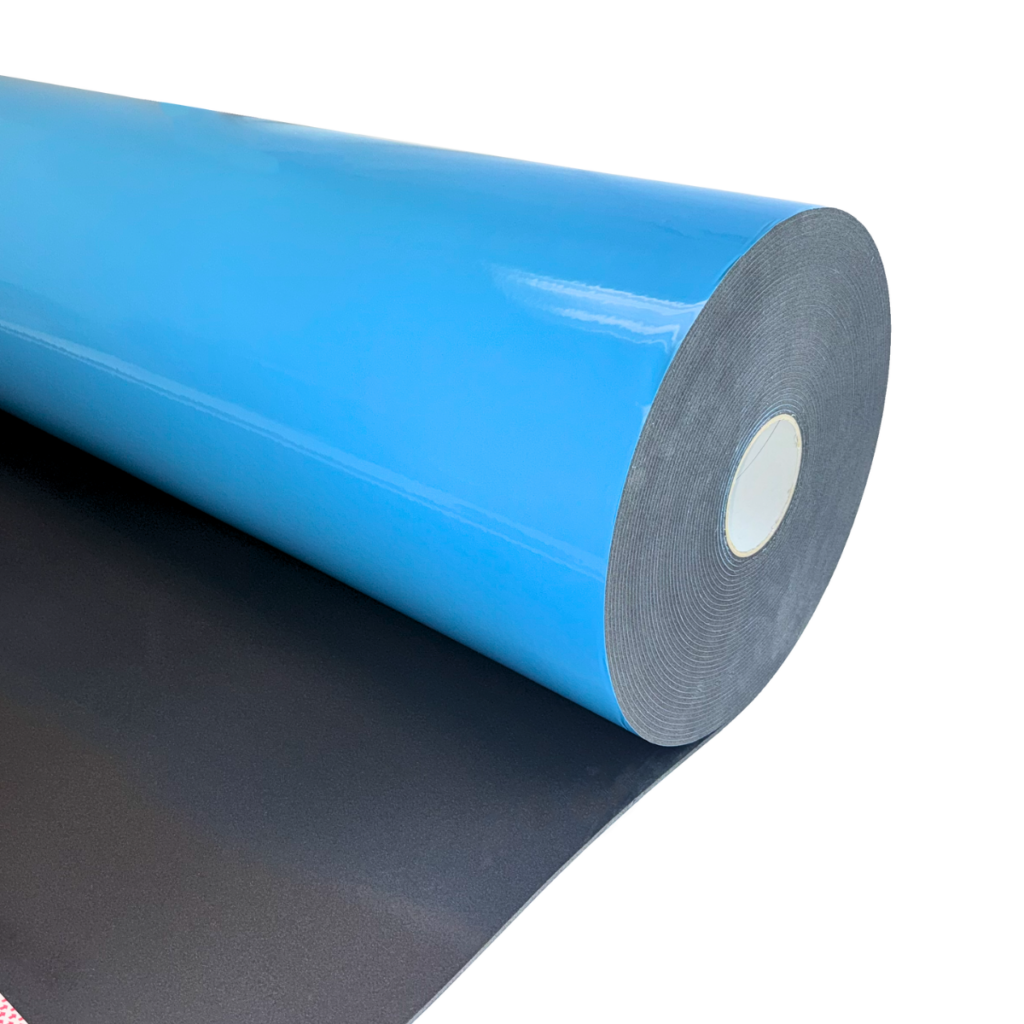

Polyethylene (PE) Foam

Polyethylene foam is a lightweight, closed-cell material known for its durability, moisture resistance, and good compression recovery. It is commonly used where a reliable seal is required without adding significant weight.

Sample product in this category:

- Closed-cell structure resists water, air, mildew, and bacteria

- Lightweight with good resilience and shock absorption

- Performs well across a wide temperature range

- Available in multiple thicknesses and densities for sealing and cushioning

- Can be supplied with PSA options

- General-purpose gaskets and seals

- Equipment panels and enclosures

- Protective spacing and vibration damping

EPDM Foam

EPDM foam is widely used for outdoor and exposed sealing applications. In addition to its weather and UV resistance, EPDM foam also offers better chemical resistance than standard neoprene foam, making it suitable for a wider range of environments.

Sample product in this category:

- Closed-cell structure provides good air and water sealing

- Good resistance to weathering, ozone, and UV exposure

- Better chemical resistance compared to standard neoprene

- Maintains flexibility over time

- Can be supplied with PSA options

- Door and window seals

- HVAC systems

- General-purpose industrial sealing

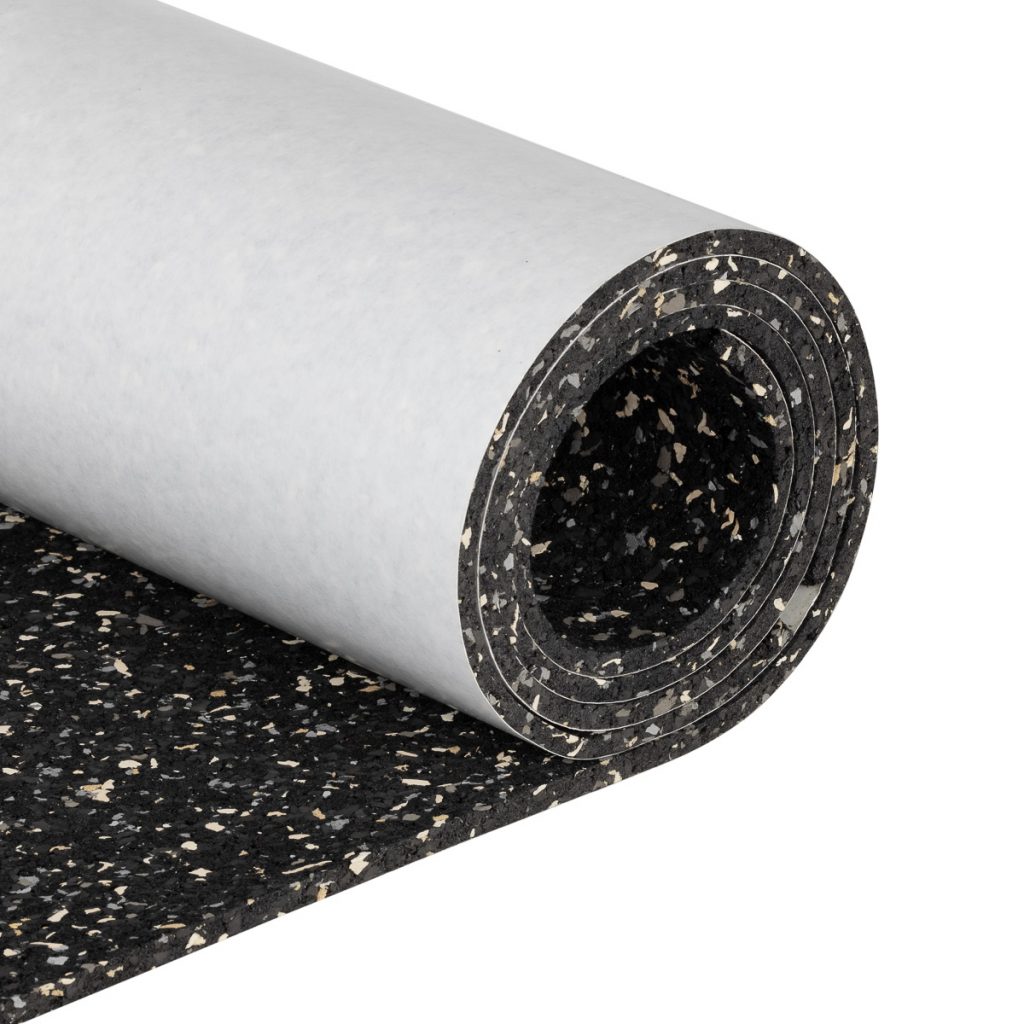

Neoprene / EPDM / SBR Blend Foam

Neoprene / EPDM / SBR blended foams offer a balanced combination of flexibility, durability, and environmental resistance. A key advantage of these materials is that all blended foams are UL-listed for flammability, which is an important consideration for many industrial and electrical applications.

Sample product in this category:

- Good resistance to oils, fuels, and mild chemicals

- Closed-cell structure for sealing against air and moisture

- UL-listed for flammability (e.g., UL 94, UL 50E)

- Can be supplied with PSA options

- Industrial and electrical enclosures

- Equipment requiring flammability-rated materials

- General-purpose sealing and vibration isolation

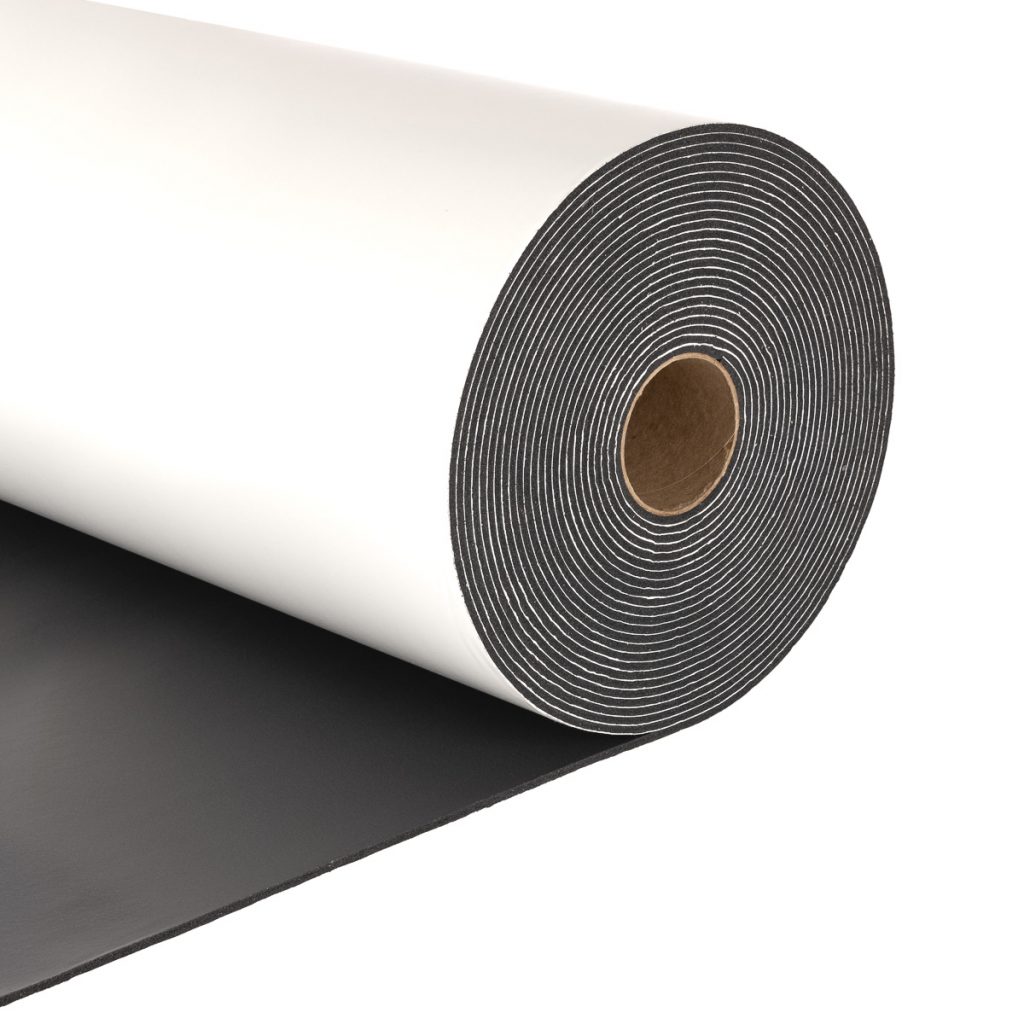

Polyurethane (PU) Foam

Polyurethane foam is available in both open-cell and higher-density forms. It is softer and more flexible than many closed-cell foams, making it suitable for cushioning, sound control, and light sealing applications.

Sample product in this category:

- Available in open-cell and denser formulations

- Highly compressible and flexible

- Good for indoor applications where moisture resistance is not critical

- Often used for comfort, sound absorption, and gap filling

- PORON® foam has an excellent compression set resistance and a low moisture absorption rate

- Can be supplied with PSA options

- Light-duty seals

- Acoustic control

- Cushioning and spacing

Silicone Foam

Silicone sponge is a closed-cell foam commonly used where temperature stability and chemical resistance are required. In addition to performing well across a wide temperature range, silicone foam also offers good resistance to many chemicals, making it suitable for demanding environments.

Sample product in this category:

- Closed-cell structure for effective sealing

- Excellent high- and low-temperature performance

- Resistant to aging and environmental exposure

- Can be supplied with PSA options

- Electrical and electronic enclosures

- High-temperature equipment

- Outdoor and harsh-environment seals

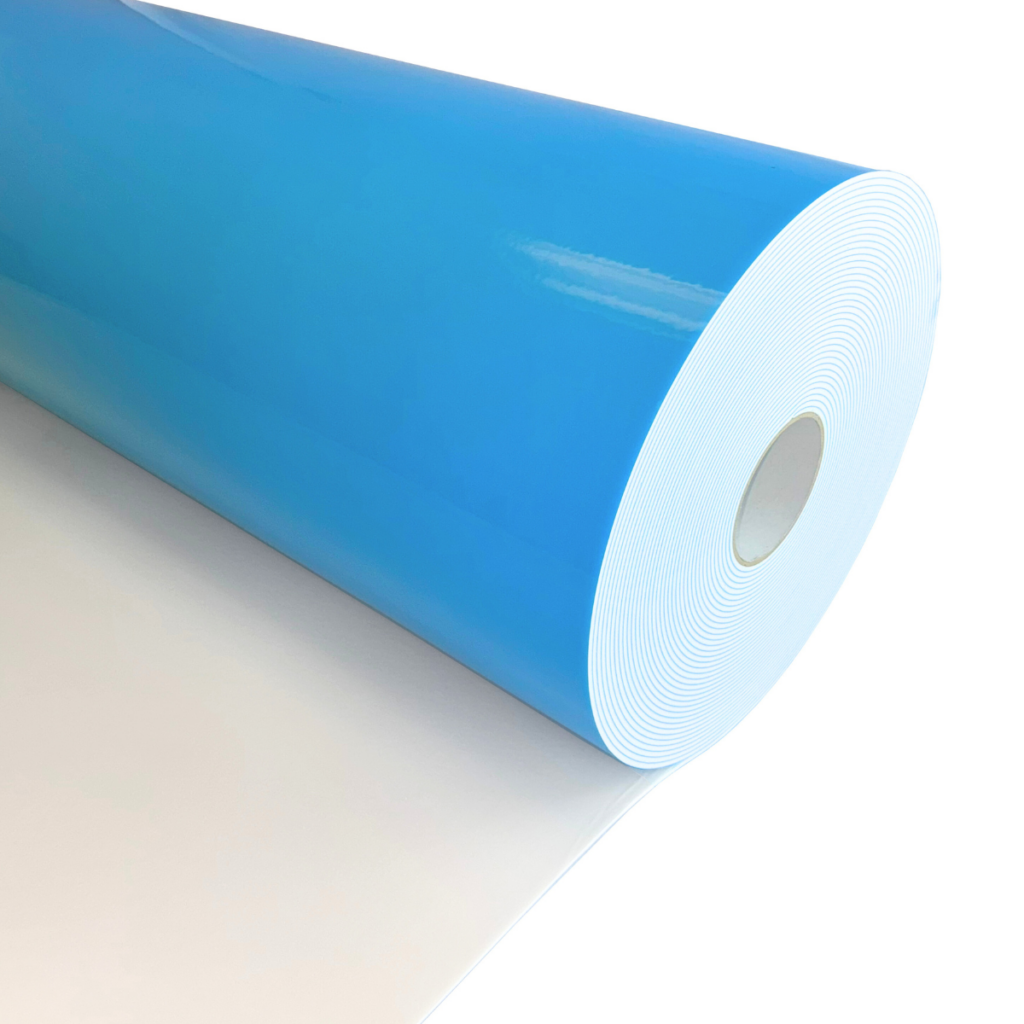

PVC Foam

PVC foam is a closed-cell material that provides a good balance of firmness and compressibility. In addition to sealing against air and moisture, PVC foam is commonly used for sound, light, and dust sealing, especially where a slightly firmer foam is required.

Sample product in this category:

- Closed-cell structure resists moisture and air

- Available in multiple density options for different sealing needs

- Good dimensional stability under compression

- Can be supplied with PSA options

- Equipment panels and enclosures

- Sound, light, and dust sealing

- Industrial gaskets and spacing applications

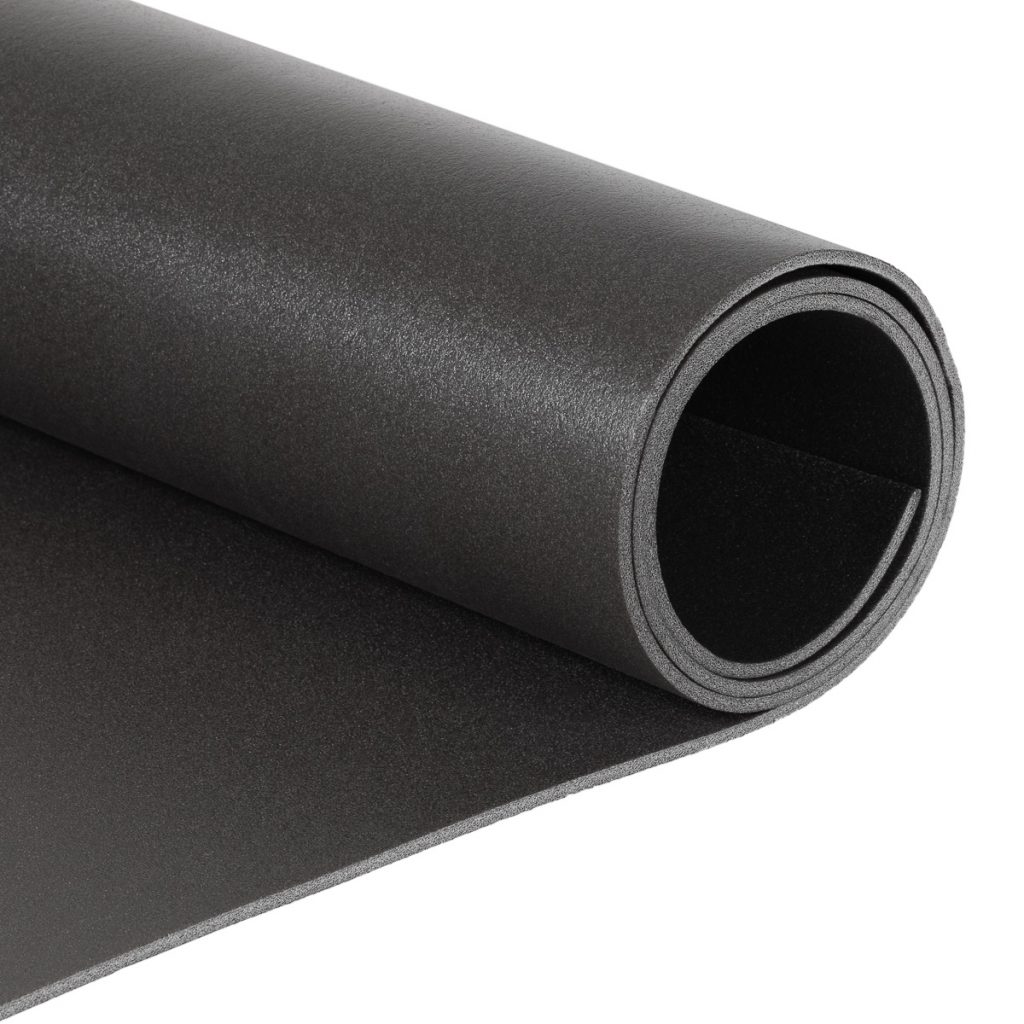

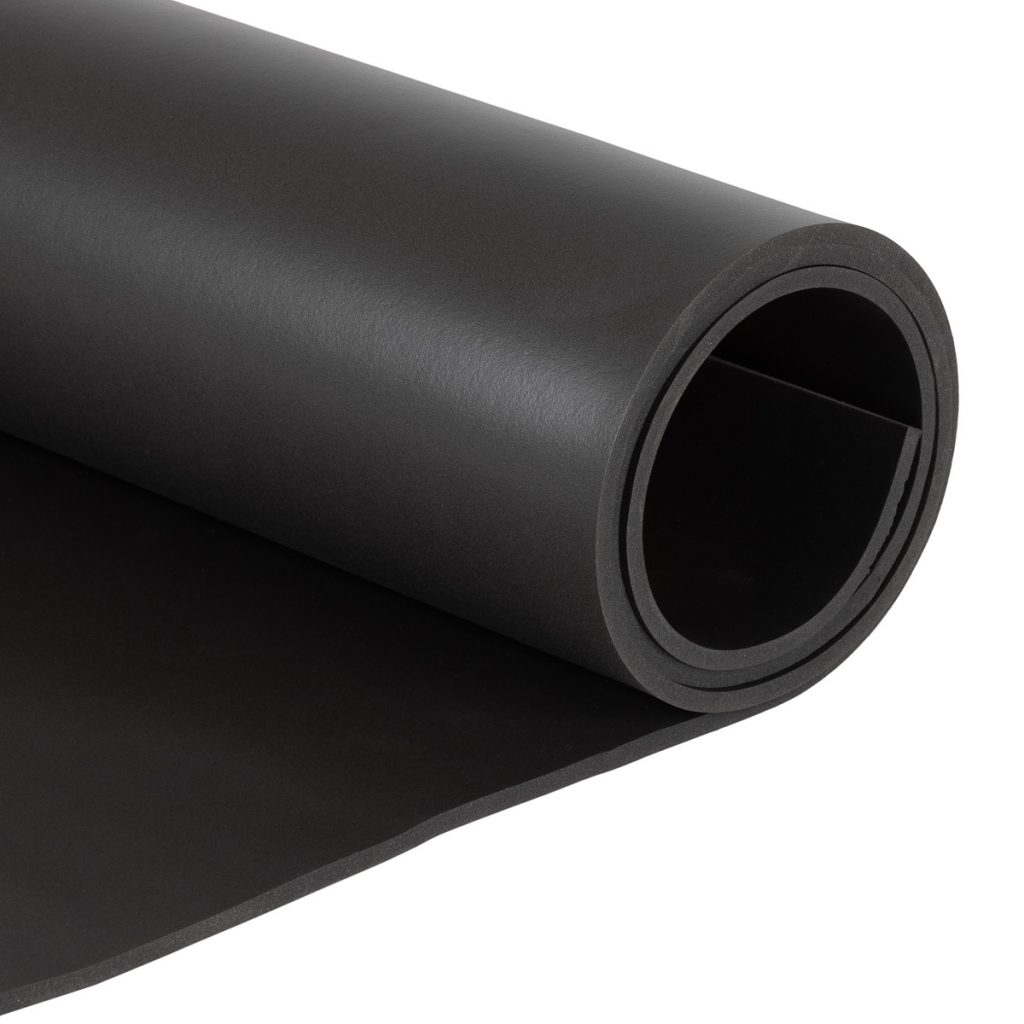

Nitrile Butadiene Rubber (NBR) Foam

NBR foam is a nitrile-based closed-cell foam known for its excellent resistance to oil and gas. This makes it a preferred choice for sealing applications where exposure to petroleum-based fluids is expected.

Sample product in this category:

- Closed-cell structure for effective sealing

- Strong resistance to oils, fuels, and hydrocarbons

- Maintains sealing performance under compression

- Can be supplied with PSA options

- Oil and gas-related equipment

- Industrial gaskets exposed to petroleum products

- Mechanical sealing where fluid resistance is required

Natural Rubber Sponge

Natural Rubber Sponge is a soft, closed-cell foam material known for its excellent flexibility and cushioning properties. It combines good compression recovery with resistance to repeated movement, making it suitable for a range of sealing and cushioning applications.

Sample product in this category:

- Closed-cell structure resists water and air infiltration

- Adapts well to surface irregularities

- Helps maintain consistent sealing contact

- Moderate resistance to oils and mild chemicals

- Soft seals where compression recovery matters

- Cushioning between panels and frames

- Light-to-medium sealing where flexibility is needed

Key Factors to Consider When Choosing Foam for Sealing

Selecting the right foam material depends on how it will perform in the application. The points below highlight the main factors that influence foam sealing performance.

Environment

Foam should suit the conditions where it will be used, including indoor or outdoor exposure, moisture, weather, sunlight, and contact with oils or cleaning agents. Closed-cell foam is often preferred in exposed or sealed environments

Compression and Recovery

Foam used for sealing should compress easily and recover well to maintain contact between surfaces over time, especially where movement or repeated compression is involved.Temperature

Foam must remain flexible within the expected temperature range. Materials that handle temperature changes better help prevent cracking, hardening, or seal failure.

Thickness and Density

Thicker foam helps fill uneven or larger gaps, while denser foam provides stronger resistance to compression. The right balance improves sealing performance and service life.

Installation

The method of installation affects foam selection. Some applications benefit from quick-apply foam, while others require foam cut to a specific shape for consistent results.Common Foam Sealing Mistakes to Avoid

Avoiding these mistakes improves sealing performance and extends service life.

- Using the wrong cell type in moisture-exposed environments

- Choosing foam that’s too soft to maintain a seal

- Ignoring UV or temperature exposure

- Selecting thickness without accurate measurement

- Assuming one foam fits all applications

Conclusion: Selecting the Right Foam Starts with the Application

Choosing the right foam material for sealing starts with understanding the application’s environment, expected service life, and performance requirements. Foam sealing delivers excellent results when matched with the right material properties.

If you need help selecting the right foam material for your sealing application, contact Custom Gaskets to speak with a material specialist and get guidance tailored to your needs.