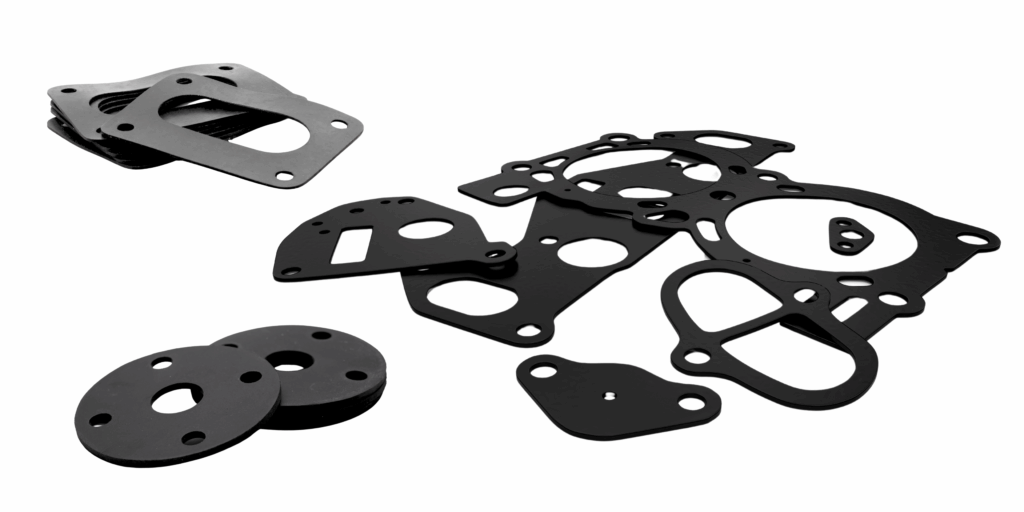

Types of Neoprene Gaskets and How They’re Used in Industry

Selecting the correct gasket material is a common challenge in industrial maintenance and equipment design. When environmental conditions vary, such as exposure to water, intermittent oils, vibration, temperature changes, or outdoor weathering, a single rubber type rarely fits every requirement. This often leads to premature gasket wear, poor sealing performance, or unnecessary equipment downtime.

This article provides a simple, practical overview of the main types of neoprene gasket materials and their common uses in industry. Learn more about different gaskets in our Gaskets 101 article.

Why Neoprene Is a Popular Gasket Material

Neoprene is a synthetic rubber made from chloroprene. It’s widely used as a general-purpose gasket material because it offers a good balance of properties:

- Handles water, weather, and ozone much better than many basic rubbers

- Provides moderate oil and fuel resistance, enough for many plant environments

- Resists many fats, greases, and mild chemicals

- Has good compression and recovery, so it seals well under bolt load

- Often includes inherent flame-retarding behaviour

- Works across a useful temperature range, typically around -20 to +170°F (-29 to +77°C) for standard grades, and higher for some premium ones

Because of neoprene’s balanced properties, it is often selected for environments with mixed service conditions such as intermittent oil contact, routine cleaning agents, outdoor exposure, and equipment vibration.

The Main Types of Neoprene Gasket Materials

Custom Gaskets Ltd. offers several neoprene options: solid sheet or cut, premium industrial grades, fabric finish, and reinforced cloth-inserted materials, each suited to different sealing and performance requirements across industrial applications.

1. General-Purpose Neoprene Sheet (Standard Neoprene)

A standard neoprene sheet is used for many everyday gasketing jobs.

Standard neoprene sheet is suitable for everyday industrial sealing where conditions are stable and non-critical:

- Comes in several hardness levels (durometer). 40–60 Shore A for most gasket work

- Temperature range around -20 to +170°F (-29 to +77°C), depending on grade

Typical uses include:

- Flange gaskets in low to moderate pressure lines

- Rubber washers and simple seals

- Pads, cushions, and bearing pads under equipment

- Strips and blocks for vibration isolation

- Non-critical service operating pressures and temperatures

2. American Biltrite™ Neoprene Grades

Custom Gaskets supplies several American Biltrite™ neoprene sheet grades that are commonly used for industrial gasketing. These materials share the same base formulation but differ in hardness, surface finish, and mechanical characteristics, allowing users to choose a grade that aligns with specific sealing requirements.

Neoprene AB-255 serves as a good reference point. It is:

- A smooth, black industrial-grade sheet

- 50 durometer (Shore A)

- Suitable for gaskets, washers, and general sealing where mild oil resistance is required

- Rated for approximately -20 to +190°F (-29 to +88°C), depending on installation conditions

AB-245 and AB-260 follow a similar pattern, but each offers distinct performance characteristics:

- Different hardness levels, providing softer or firmer sealing depending on the application

- Different surface finishes, including smooth or matte options

- The same overall role as general-purpose neoprene, but with more controlled hardness and physical properties for consistent performance

Typical uses include:

- Manufacturing and OEM equipment, such as pump base gaskets and machine covers

- General industrial plants that have occasional oil or grease, but not aggressive solvents

- Pads and spacers that require moderate load resistance and occasional movement

3. Garlock® 7986 Premium Neoprene

For more demanding service, Custom Gaskets offers Garlock® 7986 neoprene sheet.

This is a premium neoprene rubber with the following properties:

- 60 durometer hardness

- Temperature range about -20 to +250°F (-28 to +121°C)

- Good resistance to petroleum-based oils, ozone, weather, and many chemicals

- Higher tensile strength and better durability than basic grades

Typical uses:

- Flat-face flange gaskets on pumps and piping where higher temperatures are expected

- Seals in mechanical equipment that sees both outdoor exposure and oil or fuel splash

- Heavy-duty pads and bumpers where tear strength and wear resistance matter

This grade is a suitable option when applications approach the upper limits of standard neoprene in temperature, bolt load, or mechanical stress. Its higher tensile strength, wider thermal range, and improved resistance to deformation help maintain sealing performance under more demanding conditions.

4. Fabric-Finish Neoprene

Fabric-finish neoprene has a slightly textured surface (often described as “cloth finish”).

While the core material is still neoprene, the surface treatment can help:

- Improve handling and grip during cutting and assembly

- Provide a better surface for some bonding or adhesive applications

- Reduce sticking between layers when stacked or rolled

Common uses include:

- Bearing pads and support pads under equipment or structures

- Gaskets where the surface needs a bit more friction against metal or other substrates

- Lining, bumpers, and wear strips in general industrial service

This material is frequently chosen when a textured surface is needed to improve grip, positioning, or bonding performance during installation.

5. Cloth-Inserted Neoprene

Cloth-inserted neoprene (C.I. neoprene) includes one or more layers of fabric reinforcement inside the rubber.

This gives the sheet:

- Higher tear resistance

- Better dimensional stability under high bolt loads

- Less creep and extrusion when compressed

- Added strength when used as strips or pads

Where cloth-inserted neoprene is helpful:

- Flange gaskets with high bolt torque or wide gasket widths

- Strips and skirting that might be pulled or dragged during use

- Machine pads that see repeated impact, movement, or edge loading

Cloth-inserted neoprene is recommended when higher bolt loads or mechanical stresses cause standard neoprene to deform, as the embedded fabric layer helps the material maintain its shape and sealing performance.

6. Nylon-Inserted Neoprene

Custom Gaskets also supplies Nylon-Inserted Neoprene, a reinforced material designed for applications that require greater tear strength and improved dimensional stability. A woven nylon layer is embedded within the sheet, giving it added strength without significantly increasing thickness.

This reinforcement helps the material resist stretching, deformation, and edge extrusion under load.

Typical characteristics include:

- Higher resistance to tearing and elongation

- Improved stability under bolt load

- Reduced risk of extrusion or creep

- Good performance in pads, strips, and skirting

- Suitable for light oil and general industrial environments

Where nylon-inserted neoprene is often used:

- Equipment pads and supports with repeated movement or vibration

- Strips and mechanical barriers where stretching is a concern

- Gaskets under higher compression

- Industrial skirting, bumpers, and reinforced components.

How These Neoprene Types Are Used in Industry

Manufacturing and OEM Equipment

Many equipment builders and maintenance teams use neoprene because it covers several needs at once:

- Gaskets and seals for gear covers, doors, and windows

- Vibration pads under pumps, compressors, and small machines

- Washers and spacers in assemblies where some flexibility is helpful

- Machinery panels where noise and vibration should be reduced

Construction, Doors, and Building Products

In construction and building products, neoprene strips and gaskets help with:

- Weather sealing – around doors and access hatches

- Noise reduction – between metal panels or frames

- HVAC equipment – access panels and duct doors

- Thermal movement – allowing some flex without breaking the seal

Neoprene is often chosen for indoor/outdoor applications that such as generators, rooftop units, and service enclosures.

Mixed Water, Oil, and Chemical Environments

Neoprene occupies a balanced position between EPDM, which performs well in water and weather exposure, and Nitrile which has strong resistance to oils:

- Regular water and weather exposure

- Periodic contact with oils, greases, or mild chemicals

- Simple flange gaskets where conditions aren’t extreme

For more aggressive chemicals or very high temperatures, we recommend FKM (Fluoroelastomer) and Silicone rubber.

How to Choose the Right Neoprene Gasket Type

When you’re narrowing down which neoprene to use, it helps to ask a few simple questions:

- Where will the gasket be used?

Water, outdoor weather, oil mist, cleaning chemicals, or a mix of these? - What is the temperature range?

Stay within the limits of the specific product (for example, AB-255 around -20 to +190°F, Garlock 7986 up to +250°F). - How much load and movement is there?

High bolt loads or constant movement may benefit from cloth-inserted or firmer grades. - How soft or firm should it be?

Softer grades (around 40–50A) help seal rough surfaces and firmer grades (60–70A) keep tighter dimensions and resist extrusion. - Do you need extra strength or durability?

Premium grades like Garlock 7986 or cloth-inserted neoprene are worth considering when failures are costly.

Neoprene is not just one rubber; it’s a family of materials that can be tuned by hardness, reinforcement, and finish. When you match the right neoprene type to your media, temperature, and mechanical conditions, you get longer gasket life, fewer leaks, and less downtime.

If you’re unsure which grade is best for your application, contact our gasket specialist for advice. Share your operating conditions, and we can help you choose the most suitable neoprene or suggest a better material.