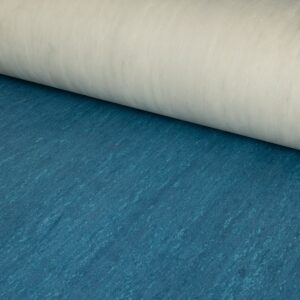

Compressed Sheets

The products displayed below should serve as a general guide only for selecting suitable gasket materials and are based on the manufacturer’s chemical resistance tables.

Showing all 26 results

-

Compare

BLUE-GARD® Style 3000

Aramid Fibers -

Compare

BLUE-GARD® Style 3200

Aramid Fibers -

Compare

BLUE-GARD® Style 3300

Aramid Fibers -

Compare

BLUE-GARD® Style 3700

Aramid Fibers -

Compare

CG1001

Aramid Fibers -

Compare

CG20 Fiber

Cellulose Fibers -

Compare

Durlon® 7900

Aramid Fibers -

Compare

Durlon® 7910

Aramid Fibers -

Compare

Durlon® 8300

Carbon Fibers -

Compare

Durlon® 8400

Phenolic Fibers -

Compare

Durlon® 8500

Aramid Fibers -

Compare

Durlon® 8600

Aramid Fibers -

Compare

Durlon® 8700

Aramid Fibers -

Compare

Durlon® 8900

Aramid Fibers -

Compare

Frenzelit® N-5408 Beater Add

Cellulose Fibers -

Compare

Garlock® 5500

Inorganic Fibers -

Compare

Garlock® 9800

Carbon Fibers -

Compare

Garlock® 9850

Carbon Fibers -

Compare

Garlock® 9900

Carbon Fibers -

Compare

KLINGERSIL® C-4401

Aramid Fibers -

Compare

KLINGERSIL® C-4408

Aramid Fibers -

Compare

KLINGERSIL® C-4430

Aramid Fibers -

Compare

KLINGERSIL® C-4433

Aramid Fibers -

Compare

KLINGERSIL® C-4500

Carbon Fibers -

Compare

MULTI-SWELL™ Style 3760

Synthetic Fibers -

Compare

MULTI-SWELL™ Style 3760-U

Synthetic Fibers

All substances are evaluated for their effect on the gasket at ambient temperature (-40°F to 90°F/-40°C to 32°C) unless otherwise stated. For different conditions of fluid concentrates, internal pressures, or temperatures; please consult Custom Gaskets Ltd. for technical guidance. The provided information are recommendations and built on laboratory or field tests. No guarantee can be given by Custom Gaskets Ltd. as the actual performance depends on the application and handling by the end user.